SNE MCI multi-photocatalytic air purification

An unhealthy environment

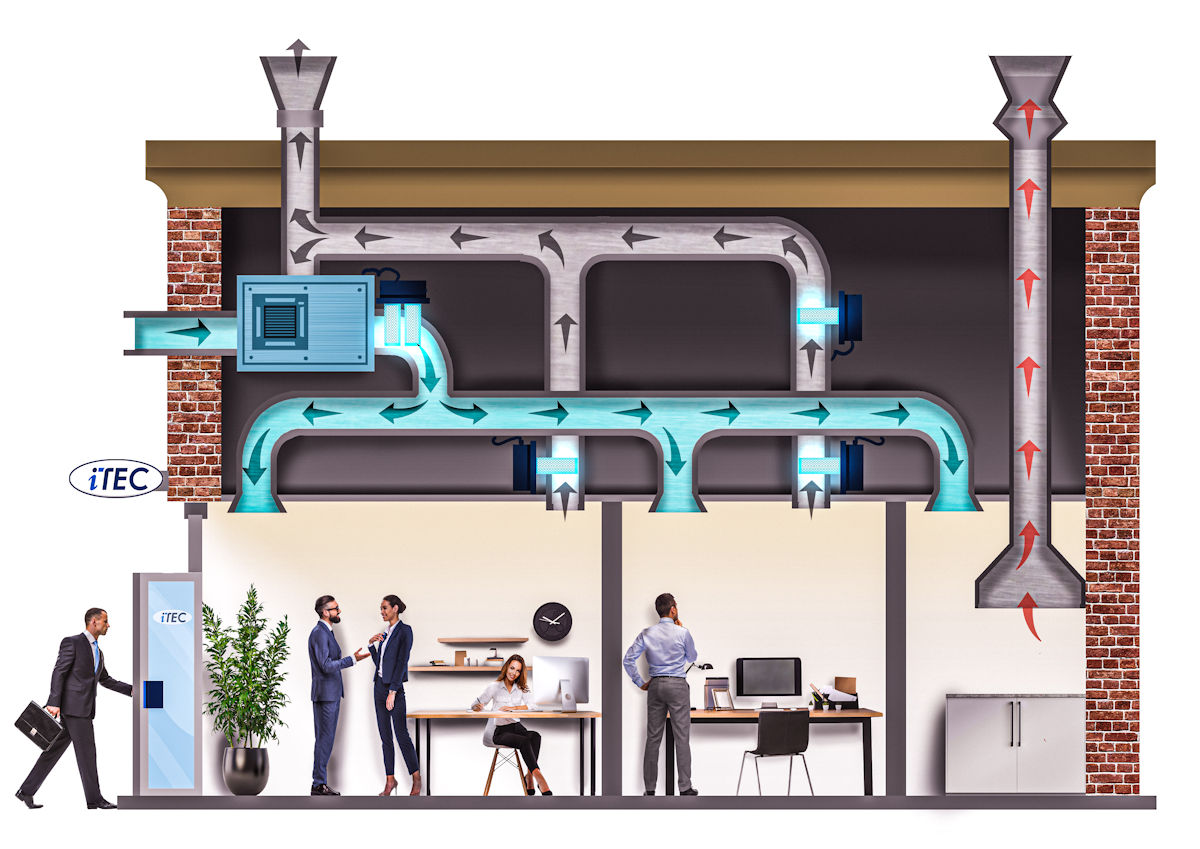

A HVAC (Heating Ventilation Air Conditioning) system in a building, rig or vessel is comparable to the human respiratory system. It supplies the inhabitants with treated air (heated, cooled, ventilated) just as the respiratory system provides the circulatory (blood) system with oxygen. Both systems are indispensable to let the inhabitants or the body survive.

But a HVAC system can also be a distributor or the source of hazardous pollutants, the often dark and moist circumstances provide many germs (bacteria, molds, spores, viruses etc) the perfect breeding ground to grow and multiply and threaten the health of the inhabitants of the building or vessel.

HVAC systems are also the distributor of pollutants like bad odors, gasses, volatile organic compounds from sources inside and outside building or vessel. These gasses like formaldehyde, benzene, toluene and xylene are emitted by many products, fluids and other sources like lacquers, paint strippers, cleaning supplies, pesticides, cargo, fuels and lubricants.

The polluted air which is often spread or created by the HVAC system leads to an unpleasant atmosphere, and threatens the health of the inhabitants.

Common symptoms are:

- Irritation and swelling of airways

- The spread of viruses like Flu

- Irritated eyes

- Headaches

- Susceptibility for colds or allergies

- Fatigue

- Difficulty concentrating

Filtration is insufficient

Like the respiratory system, a HVAC system is fitted with air filters which removes particles from the air. Gasses are not removed though and only the larger micro-organisms are caught from the air. Often the filter provides a perfect breeding ground for the germs to grow and the smaller ones will pass through the filter to be distributed across the rooms. At replacement, the filters should be treated as a biohazard even.

Advanced active air purification for clean and healthy air

With advanced level and electronic disinfection and purification technology and self-owned property rights, Multi Catalytic Ionization Technology (MCI) was developed independently by New Environmental International Company. This technology is combined with high intensity UV light produced by special quartz ultraviolet tubes and (if necessary) safe O3 without secondary pollution such as nitric acid and nitrogen oxides. The ultraviolet light (254 or 184 nm frequency) in combination with the TiO2 catalysts produce hydroxyl radicals. hydro-peroxide, super oxide ions and negative ions, as well as other catalysts which help purify air all round and swiftly. This process kills over 90% of bacteria, viruses, allergen, germs and micro-organisms.

The MCI TiO2 technology is also effective in oxidizing and reducing chemical gasses, volatile organic compounds, smoke and odors to improve the air quality indoors. The hydro-peroxides and hydroxyl radicals revolve quickly and no chemical residues or secondary pollution remains after the pollutants are oxidized.

The MCI multi-catalytic air sterilization system is, amongst other things, effective against:

Micro-organisms and allergen:

- Bacteria(99.9%)

- Viruses (99.9%)

- Molds (99.9%)

- Allergen

- Pollen

Volatile organic compounds and gasses:

- Formadehyde

- Xylene/toluene

- Benzene

- Trichloorethylene

- Chloroform

- Ammonia

- Alcohol

- Acetone

The SNE MCI technology is available in several forms which can be generally divided in the FAP and CAP series;

- The CAP models are developed for treatment of the air returned from rooms, this air will be recirculated and is cleaned by the CAP air purifier before it enters its second circulation, the CAP model can be used for many other placements and applications as well.

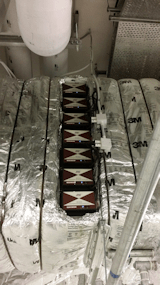

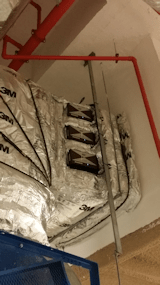

- The FAP models are developed for placement in the Air Handling unit, but can be placed in any system or air duct where the air needs to be cleaned. These are fitted with 2 UV/photocatalytic cells. The FAP models are also available as VBO model designed for exhaust fans and ducts, such as in kitchens and such, these models are developed to eliminate odors.

| Model | Floor Space | Air Flow | UV Cell | Watt |

| FAP-300DF | 100 - 300 m² | 3.500 - 6.500 m³/uur | 2x 287mm | 2x 12W |

| FAP-500DF | 300 - 500 m² | 6.500 - 12.000 m³/uur | 2x 356mm | 2x 15W |

| FAP-600DF | 500 - 700 m² | 12.000 - 17.000 m³/uur | 2x 436mm | 2x 20W |

| FAP-700DF | 700 - 900 m² | 17.000 - 25.000 m³/uur | 2x 540mm | 2x 25W |

| Model | Floor Space | Air Flow | UV Cell | Watt |

| CAP-20H | 10 - 20 m² | 400 - 600 m³/uur | 1x 127mm | <5W |

| CAP-40H | 20 - 40 m² | 600 - 800 m³/uur | 1x 127mm | <5W |

| CAP-60H | 40 - 60 m² | 800 - 1.000 m³/uur | 1x 127mm | <5W |

| CAP-80H | 60 - 80 m² | 1.000 - 2.000 m³/uur | 1x 127mm | <5W |

| CAP-100HZ | 80 - 150 m² | 2.000 - 4.000 m³/uur | 1x 287mm | <12W |

Apart from these models other custom-built products are available as well, contact us for your specific applicaiton.

Call us at +31 (0) 571 840844 for more information or send us an e-mail, our contact data can be found here.

Also have a look at our Off shore air treatment information page

Gratis verzending vanaf €75,-

Gratis verzending vanaf €75,-